Smart logistics refers to the use of advanced technologies such as the Internet of Things, big data, cloud computing, and artificial intelligence in the logistics system to enable the entire logistics system to have independent decision-making capabilities, collect and intelligently process information in real time, achieve optimal layout, and ultimately coordinate logistics The participating entities in the system are divided and cooperated with each other with high quality, high efficiency and low cost.

Smart logistics refers to the use of advanced technologies such as the Internet of Things, big data, cloud computing, and artificial intelligence in the logistics system to enable the entire logistics system to have independent decision-making capabilities, collect and intelligently process information in real time, achieve optimal layout, and ultimately coordinate logistics The participating entities in the system are divided and cooperated with each other with high quality, high efficiency and low cost. Vigorously developing intelligent logistics is the need of modern logistics development and the inevitable trend of long-term development of logistics in China's tobacco industry. Based on this background, this paper starts from the development status and construction goals of Wuhan cigarette logistics center, carries out the overall planning for the intelligent logistics construction of Wuhan tobacco logistics center, and puts forward the specific construction and implementation path, so as to provide guidance for the future development of Wuhan cigarette logistics center, which is of great significance to improve the intelligent level of Wuhan tobacco logistics, and can provide reference and reference for the intelligent logistics construction of the whole tobacco industry.

1.Wuhan TobaccoDevelopment Status and Construction Objectives of Stream

Development Status of Tobacco Logistics in Wuhan in 1.1

Wuhan Cigarette Logistics Distribution Center, as "Wuhan Regional Logistics Center", provides cigarette storage, sorting and delivery services for this unit and other municipal companies under the jurisdiction of regional logistics. With the continuous expansion of regional logistics cigarette scale, the daily operation of Wuhan cigarette logistics center has brought severe challenges. At the same time, there are some problems in Wuhan tobacco logistics center, and it is urgent to build a complete set of intelligent logistics system, including:(1) the overall planning is insufficient: the development planning of Wuhan tobacco logistics center lacks the overall layout, and it is difficult to play the overall operation efficiency of the logistics center. (2) The design of some business functions needs to be improved and lacks innovation: the logistics center has the problem of missing some business functions, and some functions lag behind in solving practical problems. (3) Information island phenomenon: the diversity of information systems, equipment and facilities leads to poor coordination between systems and insufficient interaction between data. (4) Low data utilization: The data generated in the logistics link is underutilized, especially the analysis and processing of cigarette logistics information is less.

Specific objectives of intelligent logistics construction:(1) to build intelligent logistics system through intelligent logistics construction. Promote the development of Wuhan tobacco logistics, guide the development planning of Wuhan regional logistics center, and realize the transformation and upgrading of digitalization, intelligence and intelligence. (2) Through the construction of intelligent logistics, solve the outstanding problems existing in the current regional logistics operation management and information system. Optimize the tobacco industry regional logistics management process, and gradually improve the information system construction, in order to meet the needs of operation and management, improve the efficiency of cigarette logistics operation. (3) Promote business process reconstruction and operation management mode innovation through the construction of intelligent logistics. Break the traditional functional organizational structure of the logistics center, establish a business-centered organizational structure, and at the same time change the current management model that relies on manual experience for decision-making, and realize the effective improvement of the logistics center in terms of operating costs, quality, and speed. (4) Through the construction of intelligent logistics, create a white paper on regional logistics technical standards. Through the intelligent upgrading of regional logistics, we will create standards for the construction of regional intelligent logistics in the industry and play a leading and exemplary role in the construction of regional logistics in Wuhan.

2. Wuhan Tobacco Intelligent Logistics Construction Overall Planning

First of all, starting from the management mechanism, the establishment of the overall business coordination mechanism based on the middle station, used to coordinate the operation of various departments and business logistics center. At the same time, an intelligent comprehensive decision-making platform is built to realize the interaction of information system data of each department and support the smooth operation of each department's business and system. Then it is divided into three stages to carry out digital, intelligent and intelligent construction, and finally realize the efficient operation of all aspects of cigarette logistics. The basic framework of intelligent logistics construction is shown in Figure 1.

Fig.1 Basic framework of intelligent logistics construction

2.1 the establishment of an overall business coordination mechanism based on the control center.

2.1.1 Establishment of the China-Taiwan Hub: The China-Taiwan Hub, as the overall business coordination center, effectively connects various departments and businesses, strengthens business contacts between various departments, makes various departments more closely linked, and ultimately realizes centralized management and control of the logistics center. The role of the China-Taiwan hub includes:(1) to achieve centralized control and coordination of the logistics center, through the flat management model to solve the original communication inefficiency and coordination of complex problems, to achieve business departments, functional departments, business departments and functional departments. (2) Realize the optimization of the current business process. The establishment of the China-Taiwan hub will integrate the current business process and make the business process smoother, that is, to solve the problem of poor business connection between various departments of the logistics center, and to realize the smooth connection between various departments and the China-Taiwan organization in handling business.

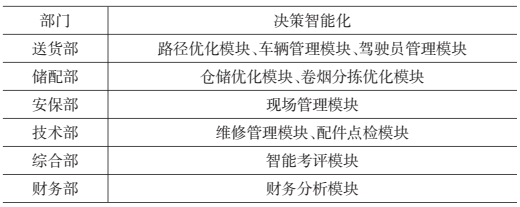

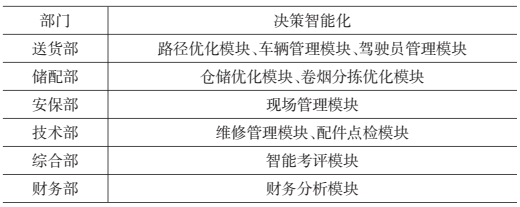

2.1.2 Establish a smart integrated decision-making platform: The smart integrated decision-making platform serves as a hub for connecting the information systems of various departments, unifying and coordinating the systems of various departments to form an integrated platform for the information system of the logistics center. The platform transmits, analyzes and processes the business data of the logistics center, thus forming an intelligent decision-making module for each department and an intelligent decision-making module for the logistics center as a whole. The role of the intelligent integrated decision-making platform includes:(1) to achieve data interaction, the information system of each department and the information platform docking, each department can achieve data docking across the system, to achieve the purpose of logistics center information flow. (2) Support the operation of various departments and systems. As the center of data processing, the processing results and instructions are transmitted to the business systems of each department, and the business systems of each department operate according to the instructions and feed back the implementation to the intelligent information platform. The intelligent integrated decision-making platform is shown in Figure 2.

Figure 2 Smart integrated decision-making platform

2.2 Digital Phase Construction Planning

The digital stage is first through the data acquisition equipment, in accordance with the requirements of standardization, to carry out "people, goods, things" data collection, and then through the network communication technology to transmit the data to the platform for storage, and finally through the platform to achieve business process information. The construction of the digital phase is shown in Figure 3.

Figure 3 Specific flow chart of digital construction

2.2.1 Data standardization:

Data standardization is the operation of standardizing the data collected in the logistics link, realizing the unification of the collection, transmission and storage data in format, coding, interface and so on. The role of data standardization. (1) Solve the problem of information island. Establish a data standard system, eliminate the poor connection between the information systems of various departments, realize the data exchange between departments, and strengthen the interaction between the systems, so that the value of data can be brought into full play. (2) Strengthen effective collaboration between departments. By opening up data silos between internal systems, information turnover is accelerated, making inter-departmental business processes more efficient and synergistic. The specific contents of data collection, transmission and storage standardization are shown in Table 1.

Table 1 Data CollectionSet, transmission, storage standardization

2.2.2 Data collection, transmission and storage:

(1) Data acquisition: Data acquisition is to obtain data such as vehicle location and driving status through satellite positioning, RFID and other technologies, obtain data such as equipment status through various sensing equipment (RFID, sensors, etc.), and obtain data such as equipment, personnel working status, cigarette appearance and other data through video, which mainly involves automatic identification and perception technology, positioning and tracking technology. (2) Data transmission: ① From a vertical point of view, data transmission is to upload the collected data such as the number, positioning and operating status of vehicles, personnel, cigarettes and equipment to the platform through network communication technology, and the platform then transmits the relevant instructions downward to the executive. The upward transmission of data and the downward transmission of instructions mainly rely on wireless network technology and mobile communication technology. ② From a horizontal perspective, data transmission is the flow of data between information systems in various departments through a unified data interface. The logistics center platform can be used as a hub between the various departments of the logistics center system, to achieve the "subsystem-platform-subsystem" connection. (3) Data storage: Data storage is to record various data generated in cigarette logistics activities in a certain format on the internal or external storage medium of the computer. There are currently three main storage methods, local storage, cloud storage and hybrid cloud storage. There are many data collection sources and large amount of data in the cigarette operation link, so the choice of storage method is very important. After fully considering the cost, data scale, computing power and other factors, the above three storage schemes are evaluated and the scheme that best meets the actual situation is selected.

2.2.3 Process informatization:

Business process informatization refers to the use of informatization tools to assist in the promotion, circulation, assistance and management of a series of activities in a certain operation link. Its essence is to realize the data capture of the whole business process and retain all information. The role of process informatization includes:(1) real-time collection of business process operation data. (2) Real-time online display of business process health status. (3) Intelligent management of data support process: Through real-time display of business process operation status, managers can keep abreast of the specific operation status of the business and do a good job of management response in a timely manner. See Table 2 for the process informatization of various departments of Wuhan Tobacco Logistics Center.

Table 2 Process informatization of each department

2.3 intelligent stage construction planning

The intelligent stage is based on the collection of business process data in the digital stage, mining the value of the current platform data, displaying the needs and problems in the business process, realizing the visualization of the process, and establishing mathematical models according to different business needs to support the business and provide intelligent decision-making for business operation. The construction of the intelligent phase is shown in Figure 4.

Figure 4 Specific flow chart of intelligent construction

2.3.1 Process visualization:

Process visualization refers to the combination of data mining technology on the basis of process informationization to visualize the problems, conditions, requirements and other information in the business processes of various departments of the logistics center to provide data support for managers. The role of process visualization includes:(1) all processes are implemented in the information system, avoiding manual operation and automating the operation of the process. (2) Using data mining technology, the tobacco enterprises in the logistics management activities of the abnormal situation and problems, the status of existing resources and specific business implementation, customer needs and other information on the system display, to provide data support for management. (3) Promote business process reengineering and realize process change and innovation. Through process visualization, we can excavate the problems in the process of process operation, break the current management mode of logistics center setting departments according to functions, change into a management mode centered on business process, and promote process reform and innovation.

2.3.2 Intelligent decision-making:

Intelligent decision-making is to change the current way of relying mainly on artificial experience to rely on systems and algorithms to make decisions. The specific work is to first identify the business that can carry out intelligent decision-making, and then for structured problems, build models, design algorithms, data testing and training, and finally land applications. Decision makers make their day-to-day business decisions intelligent by executing the output results. The application of intelligent decision-making will change the management status quo of relying on artificial experience to judge in the current operation link, improve the efficiency of logistics operation, and realize the innovation and upgrading from relying on artificial experience management to intelligent management. The intelligent decision model construction process is shown in Figure 5.

Fig.5 Intelligent decision-making process

See Table 3 for intelligent decision-making of each department.

Table 3 Intelligent decision-making of each department

Construction Planning of 2.4 Intelligent Phase

The intelligent stage is to process the data generated during the operation of the logistics center, display, evaluate and analyze the index data, and realize the real-time evaluation and early warning of the overall operation status of the logistics system. The decision makers make decisions according to the index information, risk status and risk early warning provided by the platform. The construction of the intelligent phase is shown in Figure 6.

Figure 6 Specific flow chart of intelligent construction

Wisdom evaluation is to evaluate the overall state of the logistics center and the index data of various departments by constructing the intelligent logistics index system and evaluation method, so that managers can better grasp the operation state of the enterprise and the completion of various indicators, and then identify their own gaps and deficiencies, and provide decision-making basis for daily management. Wisdom assessment is presented in the form of a large wisdom screen, through which key indicators and the overall status of the logistics center are displayed, so that managers can keep abreast of the completion status of each indicator and the overall operation of the logistics center. Wuhan cigarette logistics center wisdom big screen model as shown in figure 7.

Fig.7 Intelligent big screen model of Wuhan cigarette logistics center

The specific construction process of the evaluation method of the intelligent logistics index system is shown in Figure 8.

Figure 8 Construction process of intelligent logistics index system evaluation method

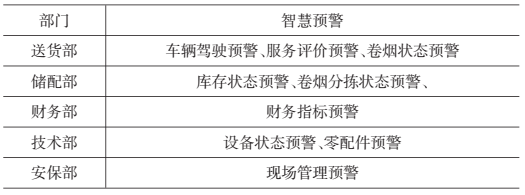

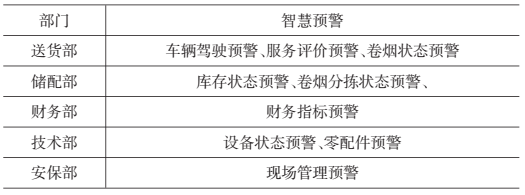

Intelligent early warning refers to the real-time analysis, display and evaluation of the main operation indicators of the logistics center, risk prediction, monitoring and early warning according to the historical data summary law and the existing state before the risk occurs. Smart early warning includes the overall early warning of the logistics center and the early warning of various departments. The overall early warning is the early warning of the overall operation status of the logistics center through the risk classification early warning mechanism. See Table 4 for details of wisdom early warning of various departments. The smart screen serves as a display platform for the overall operation of the logistics center and various indicators, and also serves as an abnormal early warning display window for the logistics center as a whole and various departments.

Table 4 Wisdom early warning of each department

2.4.3 Intelligent decision-making:

Intelligent decision-making refers to the processing of the data generated by the logistics link, the system gives the results of the processing, and provides a variety of options, decision makers combined with their own experience, knowledge and other options to choose the better solution. At the same time, in the process of data processing and analysis, adaptive and self-learning methods are used to automatically adjust the processing method according to the characteristics of the data to obtain the best processing effect. Compared with intelligent decision-making, intelligent decision-making involves more management of some unconventional events. The specific content mainly includes the management of risk events, external partnerships, key indicator prediction, key indicator early warning and intelligent decision-making in-depth application.

Implementation Path of 3. Smart Logistics Construction

The implementation of intelligent logistics planning mainly adopts the scheme from small to large and from point to surface. First, the construction of key business links, and then gradually expand the scope of construction, extended to the entire logistics center. The specific implementation process of intelligent logistics construction is mainly divided into three stages. The specific implementation progress of the three phases is shown in Table 5.

Table 5 Implementation Schedule of Smart Logistics

Specific measures:(1) Layout of data collection points and lines: ① Point: Layout of data collection equipment for key business links. ② Line: Layout data collection equipment for key business lines, that is, vertically connect the data collection of key business links in series. (2) Data transmission and storage construction: first of all, the construction of hardware foundation, while completing the construction of data standardization. ① LAN and wireless network coverage; ② cloud server and local server construction; ③ data standardization completed. (3) Process informatization: through real-time data collection, and then through the platform system, the business process status is displayed online in real time to assist in the promotion, circulation and management of business activities.

Specific measures:(1) improve the layout of the data collection surface: logistics center all business surface layout data collection equipment. That is, the business lines are connected horizontally to form the data collection network of the entire logistics center, and the data collection of each active node of the logistics center is fully covered. (2) Process visualization: Process informatization is combined with data mining technology to visualize the problems, conditions, needs and management of the business activities of various departments of the logistics center, and provide data support for managers. (3) Intelligent decision-making application: for structured problems, by building a model, designing the corresponding algorithm, according to the calculation to give the best results, decision makers choose to adopt and implement this result, to achieve intelligent decision-making in daily business.

3.3 Phase III (Implementation)

Specific measures:(1) in-depth application of intelligent decision-making: further optimize the model and algorithm, so that the model stability, flexibility, response time and effect is better. (2) Application of intelligent evaluation: to construct the evaluation method of intelligent logistics index system, to evaluate the overall status of the logistics center and the index data of various departments, to better understand the overall operation status of the logistics center and the completion of various indicators, to identify their own gaps and deficiencies, and then to clarify the focus of future work. (3) Smart early warning application: According to historical data and existing status, the key links and key indicators of logistics are displayed and analyzed, the risk status is judged in real time, risk assessment is carried out, and a risk early warning mechanism is established. (4) Intelligent decision-making application: after data analysis, the results of data analysis and processing are given from different angles, and the decision maker's experience and knowledge are relied on to make a choice. At the same time, in the process of processing and analysis, combined with adaptive technology, the data processing results are more consistent with the actual situation, in order to achieve the best results.

This paper starts from the needs of intelligent logistics upgrading and transformation in the tobacco industry. First, it analyzes the development status of Wuhan tobacco logistics center and the goal of intelligent logistics construction. Then, it puts forward the overall framework of Wuhan tobacco intelligent logistics construction, including the establishment of the overall business coordination mechanism, and the planning of the three stages of "digital", "intelligent" and "intelligent, from point to surface" principle to develop a three-stage construction program. Finally, the intelligent transformation and upgrading of Wuhan tobacco logistics center will be realized, which will provide some reference for the intelligent logistics construction inside and outside the tobacco industry.

---- Good article, worth sharing----

If there is infringement, please delete.